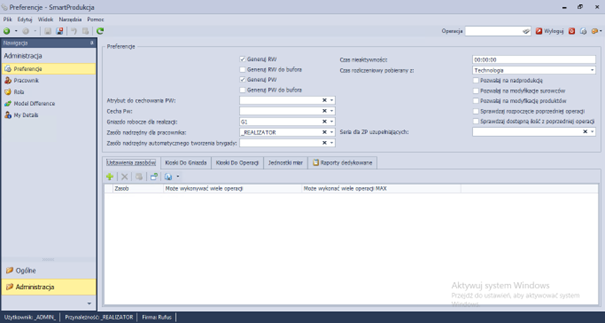

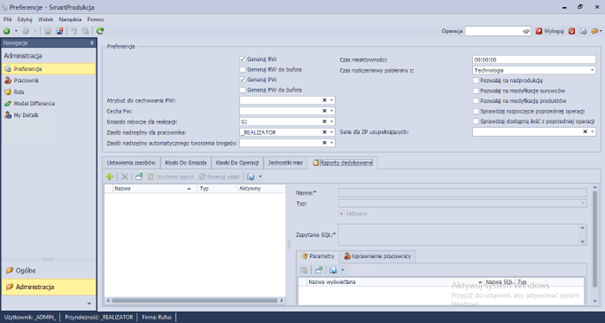

The application functionality can be configured using system settings covering the following areas:

- Automatic generation of PW/RW documents.

- Selecting the destination of document generation, where it will be generated – to the buffer or directly to the system.

- Setting a feature and attribute on the PW document (if they exist).

- Setting a work center for the implementer.

- Setting a parent resource for the employee

- Setting automatic resource creation for new brigades.

- Setting the inactivity time, i.e. the time after which the system automatically logs the user out.

- Defining where the settlement time is to be taken from.

- Setting whether overproduction, replacement of raw materials/products should be available in the implementer, and setting control of previous operations and their quantities.

- Setting a series for supplementary ZP documents.

- Setting resources in the implementer.

- Configuring kiosk slots.

- Configuring operations available on a given kiosk.

- Defining new measures for the implementer.

- Creating dedicated reports – in SQL or based on data available in the implementer.

Functionalities

- Pracownik

- Loading barcodes from the ZP printout.

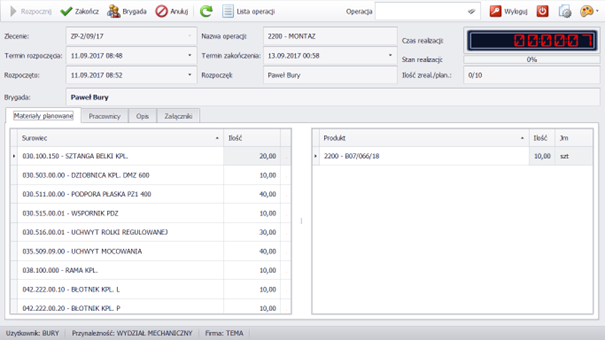

- Preview of raw materials used in a given operation and the final product of the operation.

- Possibility of using substitutes (from the product card).

- General information about the Production Order.

- Possibility of editing the composition of the Brigade performing the operation.

- Information about the operation – duration, implementation status, number of completed/planned.

- Information about the operation summary, with the possibility of manual editing of the quantities completed and damaged.

- Possibility of re-executing the same operation (on unexecuted quantities).

- Possibility of customizing the appearance of the application to the user.

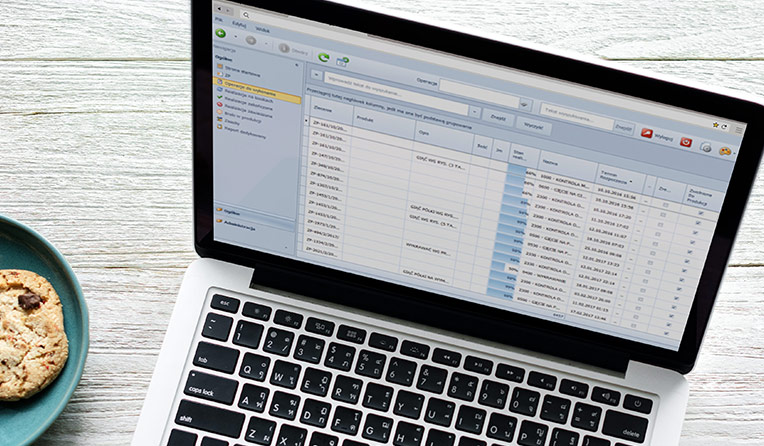

- Majster

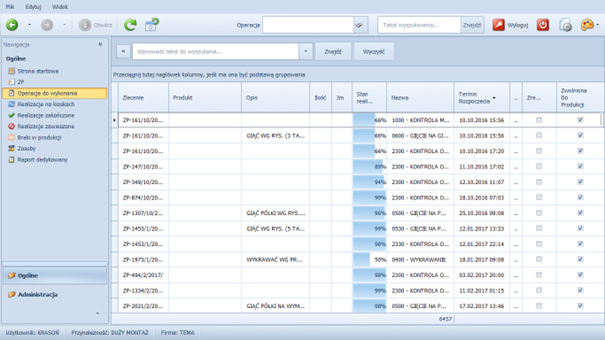

- Preview of Production Orders with the current implementation status.

- Possibility of filtering ZP by date and individual columns and grouping according to your own settings.

- Preview of operations to be performed along with the status of completion.

- Possibility of filtering and grouping operations as on the ZP list.

- Preview of operations currently being performed on kiosks.

- Preview of completed and suspended operations.

- Information on shortages in production.

- List of production resources.

- Dedicated report.

- Possibility of generating a ZP supplementing a given ZP (e.g. for shortages).

- Resuming suspended completion of operations.

- Possibility of customizing the appearance of the application to the user.

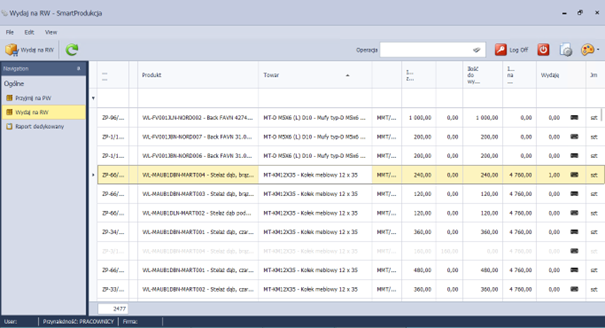

- Gospodarka materiałowa

- Issuing materials on an RW document.

- Receiving materials on a PW document.

- Using substitutes (from the product card).