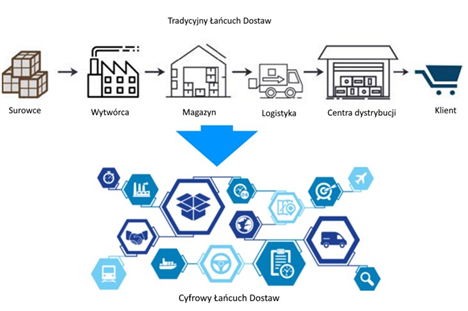

Intelligent Supply Chain Management System

The supply chain management system is an advanced tool that integrates various aspects of enterprise operations in order to optimize and monitor the entire supply process. Using the latest IT technologies and analytical models based on artificial intelligence algorithms, the system enables detailed prediction and effective resource management.

Data prediction and analysis

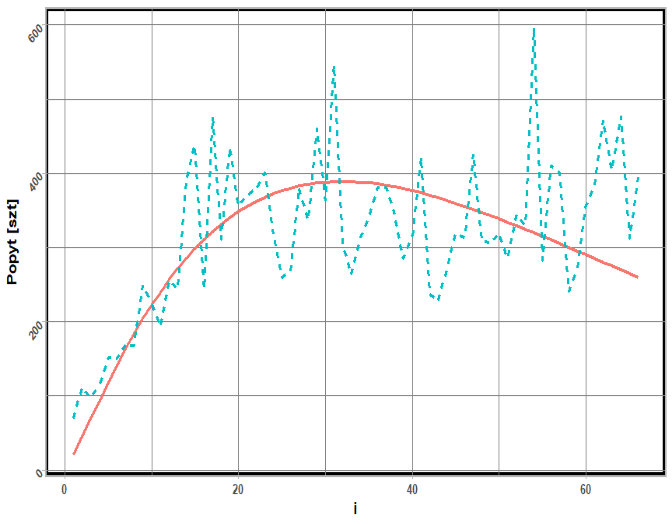

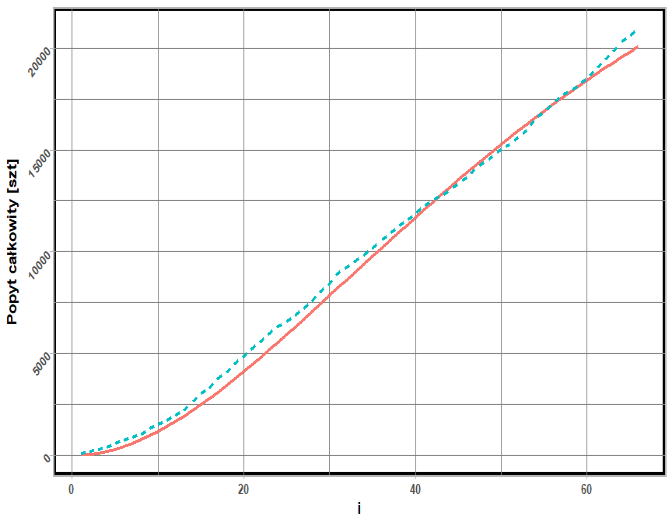

The system offers comprehensive analyses based on the company’s historical data. For example, demand prediction allows companies to prepare for future market demand. By analyzing returns and complaints, companies can proactively manage risk and improve the quality of their products. Analysis of delivery delays takes into account various factors, such as weather conditions or road traffic.

Fig 1: Example of sales trend analysis and demand prediction.

Automatic quality control

Advanced optical detection algorithms support the automation of quality control processes, identifying damage or analyzing the aging process of products. Deep learning methods enable significant increases in precision and shortens the response time to detected problems.

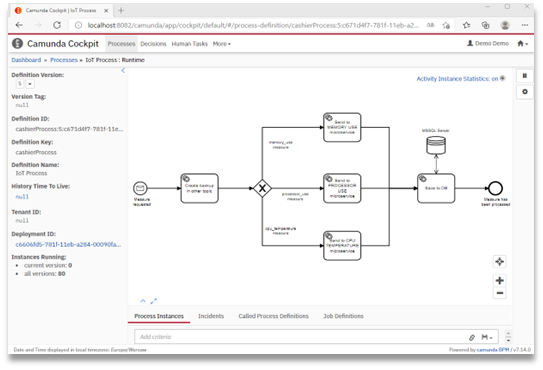

Monitoring and designing business processes

The use of technologies such as Camunda enables visualization, design and effective management of business processes. Support from Excamad and Grafana tools additionally allows for detailed monitoring of processes in real time, which translates into increased efficiency and optimization of their course.

Scalability and flexibility of the system

The system offers flexible implementation models, from local solutions (on-premise), through cloud models, to hybrid implementations. The use of architecture based on microservices and containerization allows for easy scalability of the system, enabling management of both small and large data sets using technologies such as Apache Spark.

Integration of data and tools

The system provides the possibility of integration with existing ERP, CRM, MES platforms. Thanks to the use of standard communication protocols, including REST, and tools such as Prometheus and Grafana, it is possible to effectively monitor and optimize all processes and easily adapt to the user’s needs.

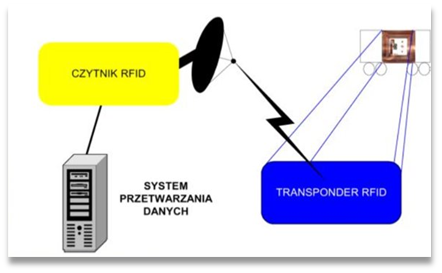

Tracking the product life cycle

Thanks to RFID technology, the system allows for tracking products at every stage of the supply chain – from warehouses, through the delivery process, to store shelves. This allows for ongoing control of inventory, optimization of delivery routes and more effective resource management.

Thanks to its comprehensive approach, the Intelligent Supply Chain Management System contributes to a significant increase in operational efficiency, minimizing costs and improving the quality of services provided.