An innovative approach to impedance tomography: machine learning and multi-frequency measurements are changing the quality of imaging

In response to the growing needs of industry in the field of precise diagnostics of processes occurring inside technological tanks, a team of scientists from the Lublin University of Technology, WSEI Academy and Netrix S.A. have developed a groundbreaking method of image reconstruction in impedance tomography (EIT). The use of machine learning combined with multi-frequency measurements has allowed for achieving unprecedented accuracy in mapping the interior of industrial reactors, making this approach one of the most advanced solutions in this field.

Previous EIT techniques have most often been based on single-phase measurements of electrical impedance, limited to a single signal frequency. The new approach eliminates this limitation by using three different frequencies – 10 kHz, 50 kHz and 100 kHz – which enables the acquisition of more complex data, taking into account both resistive and reactive components of the signal. This strategy allows for a more complete picture of the distribution of electrical properties inside the tested medium.

To process this complex, multidimensional measurement information, the researchers used a Long Short-Term Memory (LSTM) neural network architecture, designed specifically for working with sequential and variable-frequency data. Each input data set contained 448 complex values – from different frequencies – which significantly exceeds the capabilities of traditional models, which operate only on real values. This allowed for a much better representation of the structure of the tested object and increased resistance to measurement noise.

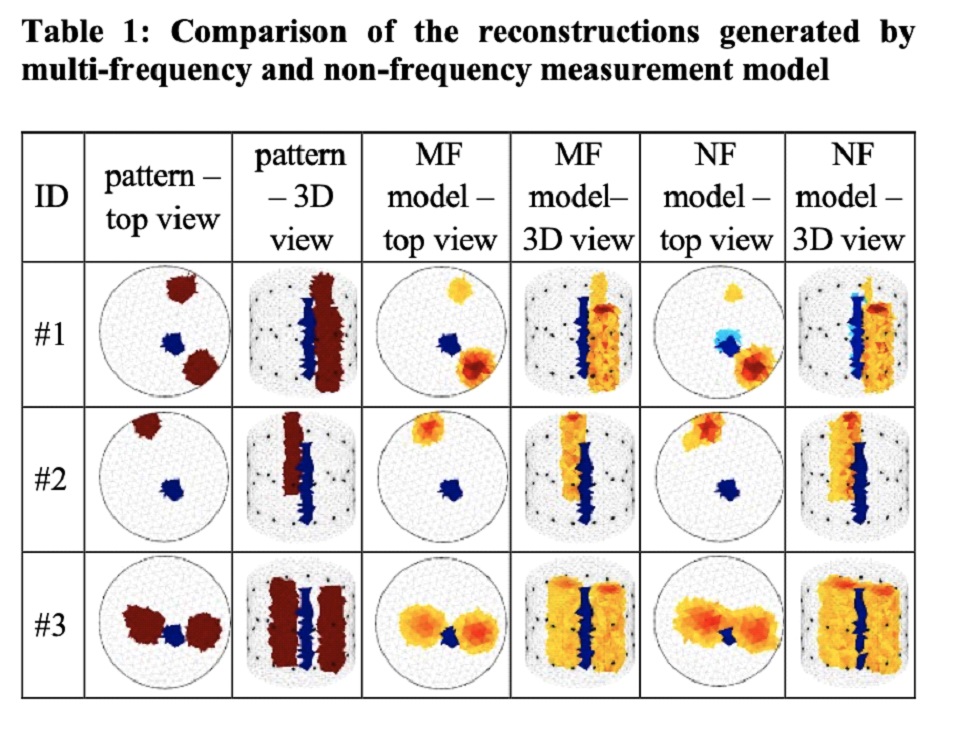

Comparisons of the performed reconstructions showed that the model based on multi-frequency (MF) analysis achieves noticeably better results compared to the standard single-frequency (NF) approach. The mean square error (MSE) was reduced by about 30%, the PSNR value increased by 1.5-2 dB, and measures such as SSIM and ICC showed significantly better agreement with the reference standard image. Reconstructions obtained using the MF model showed greater structural fidelity, which is crucial in the context of industrial applications.

The importance of this technology goes beyond the improvement of imaging quality. The developed method significantly increases the precision of diagnostics inside process vessels, reduces the impact of measurement interference and enables further automation of monitoring through the use of artificial intelligence mechanisms. This approach opens the way to a new generation of EIT systems that can be successfully used in the chemical, food, pharmaceutical and energy industries.

The research results were presented at the prestigious ACM SenSys 2024 conference in Hangzhou and published in the post-conference materials. Detailed technical documentation and the full version of the publication are available at: link to publication