Innovative method of reconstructing the interior of industrial reactors using EIT and machine learning

A significant breakthrough has occurred in the field of industrial process diagnostics. Scientists have developed an innovative method of imaging the interior of industrial reactors, combining EIT with advanced machine learning techniques. The new approach, described in detail in the journal Measurement, uses multi-frequency analysis and the architecture of deep neural networks, significantly improving the accuracy of reconstruction and resistance to interference compared to classic single-frequency methods.

At the heart of the developed technology is a sequential measurement system implemented for three frequencies: 100 kHz, 50 kHz and 10 kHz. This allows for simultaneous consideration of both resistive and reactive components of the impedance signal, which translates into a more complete representation of the processes taking place inside the reactor. This approach allows for more precise tracking of changes in the process medium and more effective detection of irregularities.

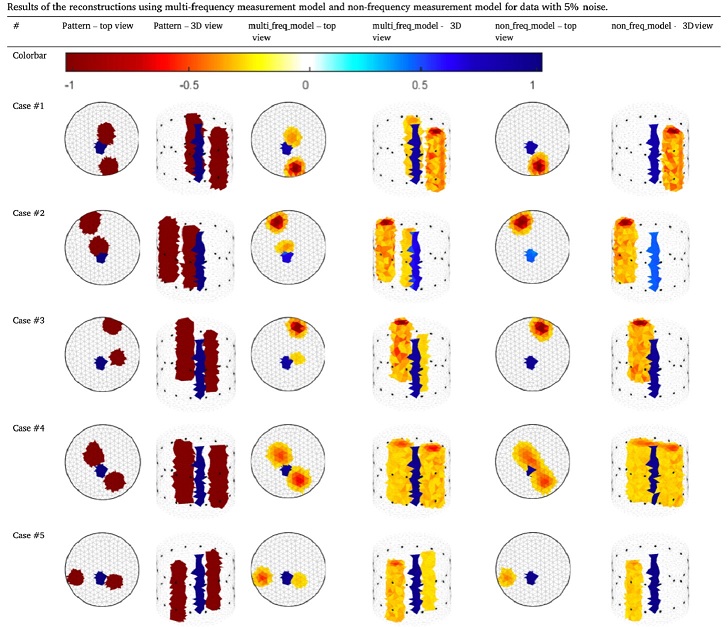

An integral part of the system is a multi-branch LSTM (Long Short-Term Memory) neural network, specially adapted to process data from different frequency bands. Thanks to the use of this architecture, it has become possible to effectively reconstruct tomographic images even in conditions of significant data noise, reaching the level of 15%. Compared to traditional solutions, the new method achieves significantly better quality parameters, including lower mean square error (MSE), higher PSNR coefficient, better result of structural consistency SSIM and higher correlation between ICC images.

The effectiveness of the method was confirmed in real conditions, by validation on a physical model of a reactor equipped with 32 measuring electrodes. The obtained results showed that the developed algorithm maintains high precision of mapping the internal structure of the process medium, despite the presence of typical measurement interferences. This confirms its usefulness in industrial monitoring and control systems.

The significance of this achievement goes far beyond the technological aspect. Efficient and accurate imaging of the reactor interior is crucial for the safety and efficiency of industrial processes in sectors such as chemistry, petrochemistry and pharmaceuticals. Traditional EIT techniques have been struggling with limitations in terms of resolution and noise sensitivity, which often hindered practical application. Integration of machine learning methods with multi-frequency analysis opens up a new area of applications, enabling not only faster detection of anomalies, but also ongoing optimization of technological processes and reduction of the risk of failures.

A pictorial comparison of the reconstruction quality using multi-frequency and single-frequency methods clearly shows the advantage of the new approach – especially in conditions of low signal-to-noise ratio.

The developed technology is a significant step towards intelligent industrial diagnostics, combining measurement reliability with the potential of artificial intelligence. More details can be found in the full version of the publication: link to the publication