Innovative Discrete Manufacturing Monitoring System Using IoT and Machine Learning

In the era of Industry 4.0, the dynamic development of digital technologies enables a radical transformation in the management and optimization of production processes. In response to the needs of modern industry, a team of scientists led by Krzysztof Król from the Research and Development Center of Netrix S.A. has developed an advanced discrete manufacturing monitoring system that integrates process simulations, Internet of Things (IoT) technology, and machine learning algorithms. The developed solution represents a groundbreaking tool that supports quality control, event forecasting, and intelligent production automation.

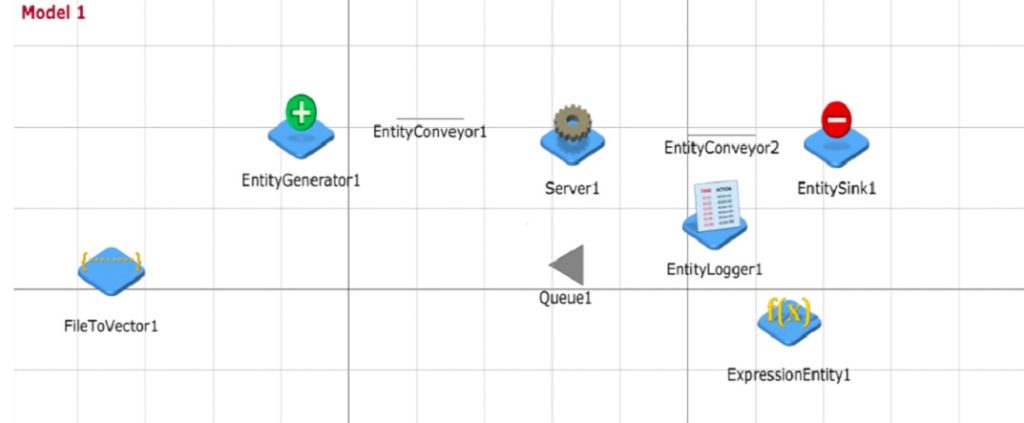

A key element of the system is the use of simulation tools such as JaamSim and SimPy, which allow for the realistic modeling of processes occurring on production lines. This makes it possible not only to accurately trace the flow of materials and identify potential bottlenecks but also to test alternative production scenarios without interfering with the actual operational environment.

The system has been integrated with IoT sensors that collect real-time data, including temperature, humidity, pressure, and acceleration. This data is analyzed by machine learning models, including random forests and artificial neural networks, enabling the rapid detection of anomalies in the process, accurate classification of shipments, and forecasting system behavior based on historical data.

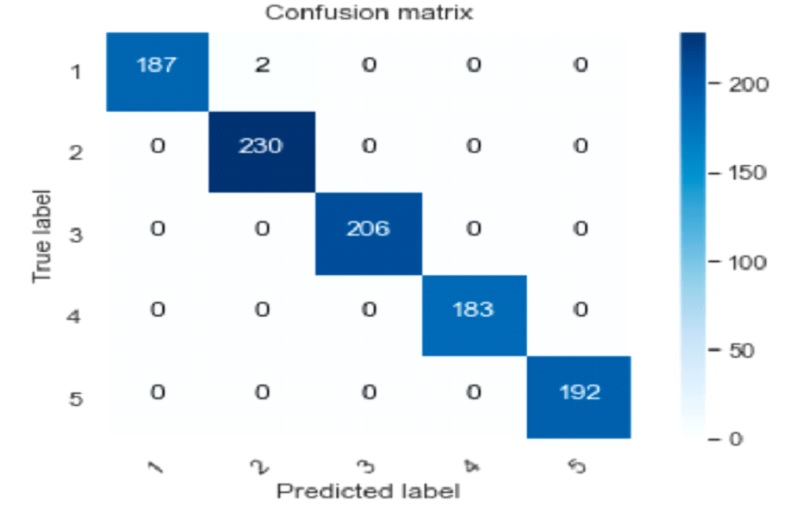

Particular recognition goes to the designed neural network model for classifying objects moving on the conveyor belt. The three-layer architecture (3-5-5), using a cross-entropy loss function and the Adam optimizer, achieved an impressive accuracy of 99.8%. This means nearly complete elimination of classification errors, which directly translates to the efficiency of the entire production process.

The system has been made available to users via an interactive web application developed using the Streamlit library. The platform allows for intuitive configuration of simulation parameters, real-time visualization of results, and testing of various production line operating scenarios. This solution not only simplifies data analysis but also supports decision-making based on evidence.

The implementation of this technology in industrial environments opens up new opportunities for intelligent production automation. The system enables better resource utilization, reduces response time to irregularities, and minimizes the risk of costly downtimes. The next step will be applying the solution in real-world conditions, allowing further validation of algorithms and their adaptation to the specifics of particular production lines.

The full version of the article is available at:

https://ersj.eu/journal/3385