Revolutionary approach in industrial tomography: ultra-detailed ultrasound scanner using machine learning

A team of researchers from the Lublin University of Technology, the Netrix S.A. Research and Development Center, the WSEI Academy in Lublin and the University of Bath have developed a modern ultrasonic tomography system (UST), which sets new standards in the field of imaging the interior of industrial reactors. The innovation of this solution lies in the integration of advanced signal analysis methods – the Hilbert transform and the discrete wavelet transform (DWT) – with a unique, two-track neural network architecture. This technology allows the creation of high-resolution images with great precision and in real time, without the need to interfere with the structure of the tank.

In industrial applications, especially in the chemical and petrochemical industries, precise monitoring of processes occurring inside reactors is crucial. Traditional imaging methods often prove to be insufficient in terms of resolution or require invasive procedures. The new UST system eliminates these limitations, enabling the detection of phenomena such as the formation of crystals or the presence of gas bubbles in a liquid, which significantly increases the efficiency of technological process control.

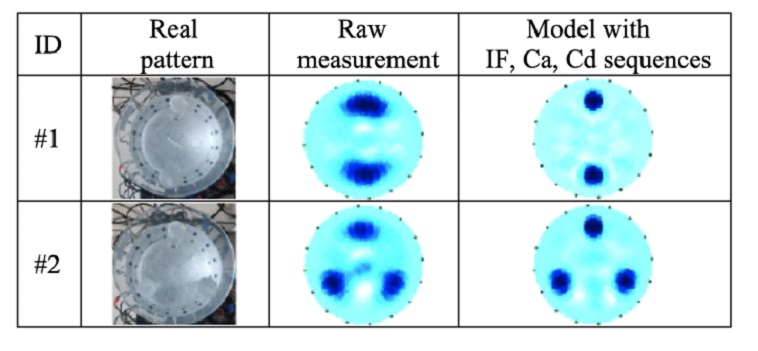

The core of the system is a dual-path neural network that parallel processes both raw measurement data and data transformed using the Hilbert and wavelet transformations. The model takes into account both the vector of 120 ultrasonic measurements and three separate signal sequences: instantaneous frequency (IF), approximation factors (Ca) and details (Cd). This approach allows for a much richer representation of information, which translates into a significantly better quality of tomographic reconstructions.

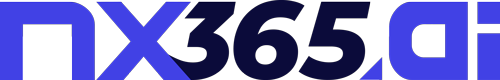

The system operates on the Raspberry Pi 4B mobile platform with dedicated software, which makes it not only precise, but also economical and easy to implement in industrial conditions. The use of 16 ultrasonic transducers placed around the tank allows for 120 measurements to be taken simultaneously in a single sequence, ensuring very high accuracy in mapping the actual conditions inside the reactor.

The results of the tests carried out on the reactor model confirm the significant advantage of the new system over conventional solutions. Tomographic visualizations made using the developed neural network better reflect the actual distribution of materials in the tank, which is crucial for the control of industrial processes in real time.

The developed system is a breakthrough in the development of industrial imaging methods. Thanks to the synergy of modern signal analysis techniques and deep machine learning, it was possible to create a solution that combines high precision, mobility and availability. This technology opens up new possibilities for the industrial industry, especially in the area of the dynamically developing chemical sector, offering an economical and non-invasive tool for ongoing monitoring of technological processes.

Want to learn more? Read the full scientific publication: link to publication