Parallel or overlapping process management

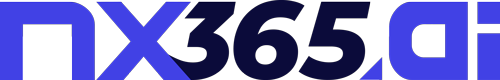

Parallel or overlapping processes are managed via the “Gantt” functionality available from the “Commissions” module. The chart displays Orders (along with planned tasks), generated from the project production plan (Projects > Process).

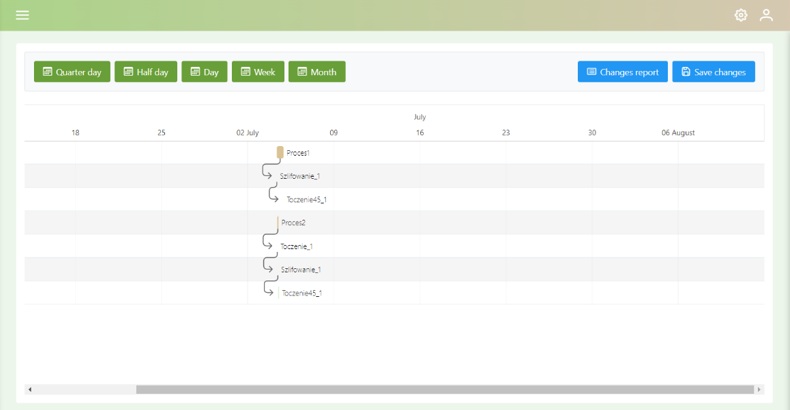

Minimizing preparation and production times

This functionality is implemented via a list of tools and orders using the selected tool. This option (ToolsOptimization) is located in the Configuration module. Possibility to replan selected orders by checking the planned execution time and cost based on the time and cost of preparing the station and neighboring orders (if several orders are performed one after another at the same station on one day, the cost and time of preparing the station is added only to the first order)

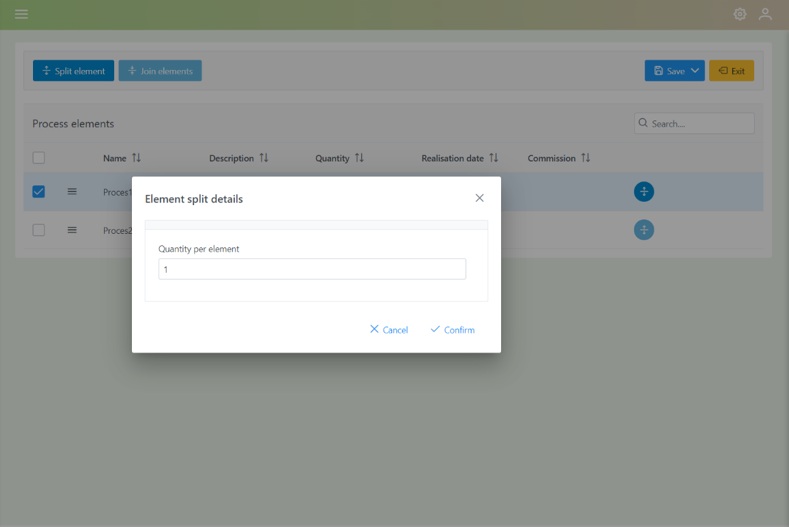

Handling and division of batch sizes

The batch size division functionality is implemented via the “Process split” option, which is available from the list of defined projects. The process division view contains a list of process elements defined within the selected project. For elements with a quantity greater than 1, a division option is available, which divides the selected element into X separate elements (where X = the number of created elements). For elements with a consistent definition, an option to combine elements is available, which results in one target element with the summed number of occurrences from all source elements.

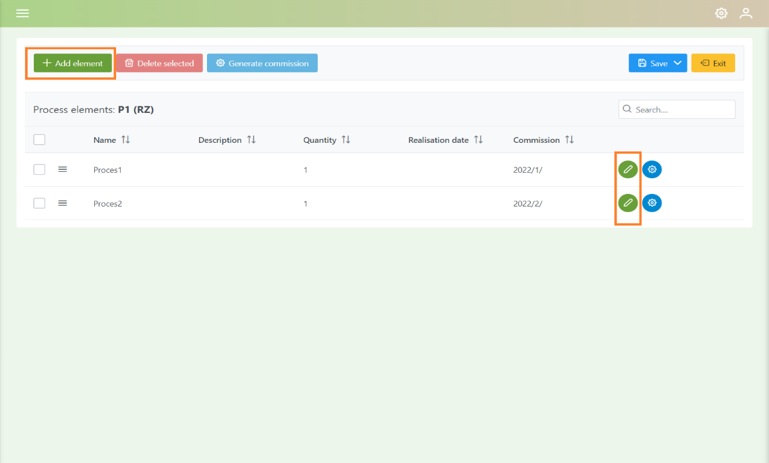

Creating a production plan

The production plan is created using the project process editor, available from the project list level. The process editor view contains a list of defined processes, along with the possibility of submitting / editing / deleting / reorganizing them and generating orders.

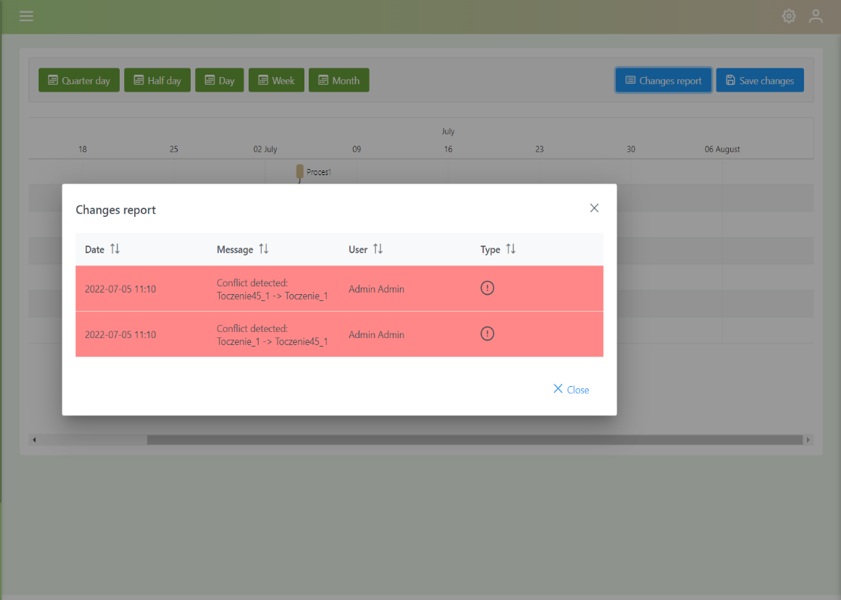

Dynamic calculation of the effects of changes

This functionality is located within the Commissions module in the Gantt chart area. It is responsible for recording changes to chart elements and the effects resulting from these changes. It displays information about changed production start and end dates, conflicts that occurred and resolved resulting from moving chart elements.

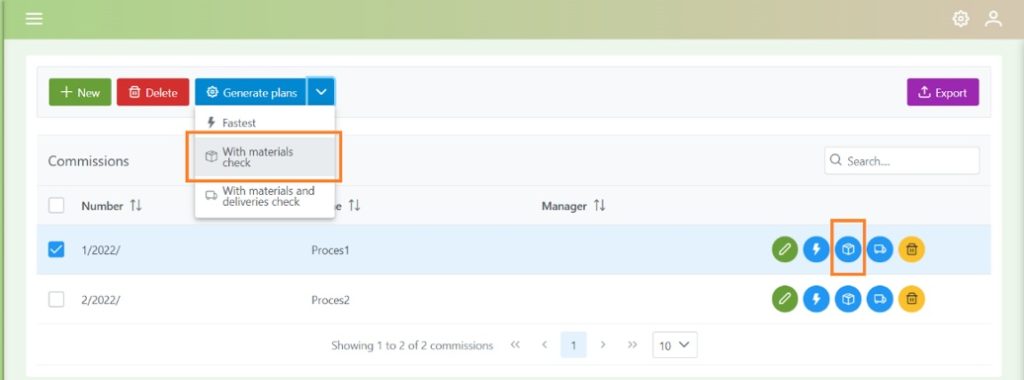

Planning taking into account the availability of raw materials

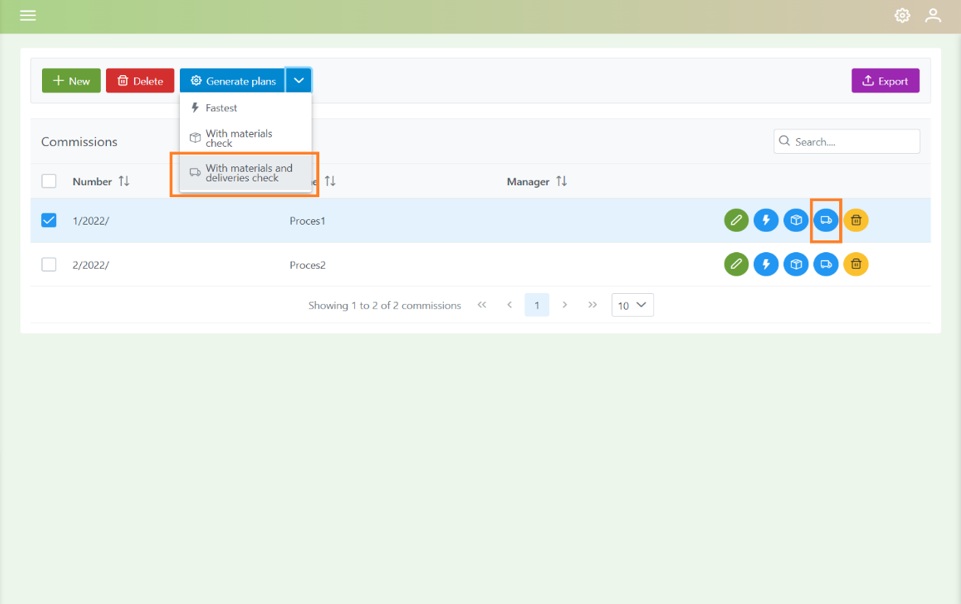

Order planning is performed from the order list level (Commissions). The functionality of planning taking into account the availability of materials is available from the “Generate plans” button (for several selected records) or from the action buttons of the selected record.

Planning taking into account the time parameters of possible material deliveries for production carried out on order.

Order planning is performed from the order list level (Commissions). The functionality of planning taking into account the availability of materials and material deliveries is available from the “Generate plans” button (for several selected records) or from the action buttons of a given record.