Modern Ultrasound Tomography Systems in Industrial Process Monitoring

A team of researchers has developed an innovative system for monitoring chemical processes, based on advanced ultrasound tomography (UST) and intelligent feedback control. This solution opens up new possibilities for controlling and optimizing reaction progress in industrial reactors, providing a higher level of precision, automation, and operational safety.

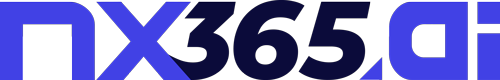

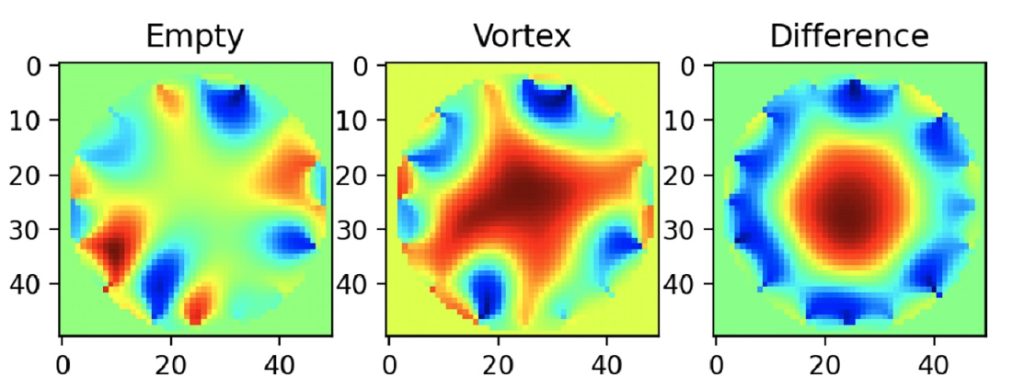

The core of the developed system is the integration of UST imaging techniques with advanced image reconstruction algorithms and industrial process control modules. By applying machine learning methods—particularly Gradient Boosted Classifiers (GBC)—the quality of internal structure imaging within reactors has been significantly improved. Compared to traditional logistic regression, the reconstruction accuracy increased by as much as 15–20%, which is crucial for early detection of inhomogeneities and precise analysis of material distribution, such as during the crystallization of active substances.

The high imaging resolution achieved through the use of mathematical modeling and optimization tools (e.g., from the SciPy package) enables effective tracking of dynamic processes, such as the mixing of liquids with solids. The system allows for real-time monitoring of changes, forming a foundation for further automation of process control.

A key element of the technology is the integration of imaging modules with an intelligent feedback-based control system. Integration with PLC systems and the use of communication protocols such as RS-232, RS-485, and Modbus allows direct control of actuators (mixers, pumps) based on the analysis of measurement sensor data (e.g., pH, temperature, pressure). The implementation of PID control algorithms and predictive control enables dynamic adjustment of process parameters to changing conditions, improving process stability and efficiency.

The developed solution finds applications in various industrial sectors where control over processes occurring in liquid environments is crucial. In the pharmaceutical industry, the system can be used to monitor the crystallization of active substances. In the chemical industry, it enables optimization of reactions in continuous reactors, while in the energy and petrochemical sectors, it supports the detection of inhomogeneities and disturbances in liquid flows.

The combination of ultrasound tomography, artificial intelligence, and automated control technologies creates an advanced tool that supports not only process supervision but also adaptive regulation. The developed system represents a step toward intelligent, self-optimizing industrial installations aligned with the Industry 4.0 concept.

The full version of the article is available at:

link to publication