Innovative Solutions in Monitoring Logistics and Production Processes: A Study on the Accuracy of Wireless Sensors

In the face of increasing market demands and advancing automation, effective monitoring of logistics and production processes has become the foundation of modern enterprises. In this context, a team of researchers led by Krzysztof Król from the Netrix S.A. Research and Development Center conducted comprehensive studies on the accuracy and reliability of wireless environmental sensors, offering an innovative approach to real-time data analysis and optimization of industrial processes.

The focus of the research was the verification of the measurement quality performed by temperature, humidity, pressure, and acceleration sensors. The experiments were based on comparing two identical sensors operating in parallel under the same environmental conditions. The analysis revealed a very high correlation between the results, confirming the stability and precision of the obtained data.

In temperature and humidity measurements, the differences between the sensors did not exceed 0.2°C and 1% relative humidity. Such accuracy ensures that systems based on these sensors can be used for continuous monitoring of storage, production, and transportation conditions of sensitive products.

The pressure sensor tests also demonstrated exceptional stability – readings differed only within fractions of a hectopascal, which is crucial in applications where even minor changes can impact the quality or safety of the process.

One of the most innovative elements of the experiment was the use of an industrial robot for dynamic testing of acceleration sensors. The device was programmed to perform abrupt, multi-axis movements, allowing the sensors’ response to dynamic changes to be tested. The results showed high signal consistency, indicating the suitability of these sensors for environments that require precise motion tracking, such as robotic production lines, internal transport systems, or autonomous logistics platforms.

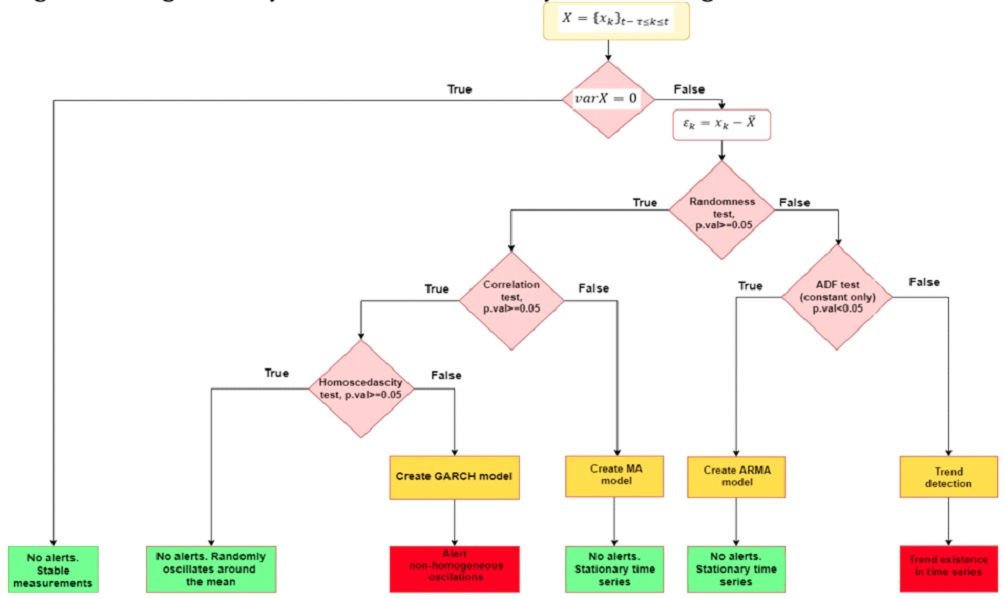

An integral part of the research was advanced statistical analysis, which allowed for the detection of trends and nonstationarities in the recorded signals. Wald-Wolfowitz, Ljung-Box, and Box-Pierce tests were applied to assess the randomness of the data, and a proprietary algorithm was developed for real-time identification of anomalies and trends. This enables the system to immediately detect deviations from the norm and generate alerts, supporting quick responses from operators and production management systems.

The results of these studies represent a significant contribution to the development of intelligent industrial process management systems. The use of precise and reliable wireless sensors combined with advanced data analysis allows for early detection of potential problems, automation of responses, and efficient optimization of operational costs. The developed technology has implementation potential not only in industry but also in sectors such as logistics, transport, healthcare, and environmental management.

The full version of the publication is available at:

https://ersj.eu/journal/3387