An innovative approach to increasing energy efficiency in industrial tomography

The research team from the Lublin University of Technology, the NETRIX S.A. Research and Development Center and the WSEI Academy in Lublin have developed an innovative system for intelligent optimization of loss functions in neural networks, which significantly improves the quality of imaging in electrical impedance tomography (EIT) used in industrial reactors. This breakthrough solution has the potential to significantly increase the energy efficiency of industrial processes, responding to contemporary challenges in the area of sustainable development.

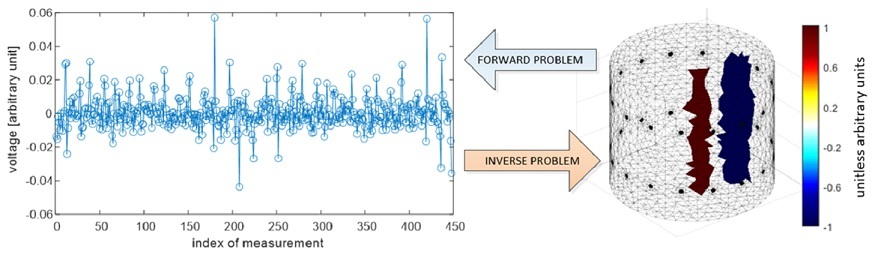

An innovative classifier has been developed, which, using machine learning methods, enables automatic adjustment of the optimal loss function to a given neural network model. So far, this selection has been made experimentally, which carried the risk of subjectivity and limited the precision of modeling. The applied recommendation system, operating on the basis of measurement data, significantly increases the accuracy of the reconstruction of the interior of industrial reactors, which in turn allows for more effective monitoring and control of technological processes.

The research used four neural network models based on the LSTM architecture, trained with different loss functions, such as HMSE, Huber, l1loss and l2loss. Each of the models was assessed in terms of the quality of the obtained reconstructions. The key element of the system is the use of an SVM (Support Vector Machine) classifier, which achieved an accuracy of 59.6% in predicting the most appropriate model for a specific set of input data. In the context of a four-class task, such a result significantly exceeds the value obtained with random selection (25%), which confirms the effectiveness of the developed method.

The system was verified using data from actual measurements taken in the Netrix S.A. laboratory. The obtained reconstructions showed high compliance with the actual geometry of the structures inside the reactor, which confirms the practical usefulness and implementation potential of the solution.

The use of an intelligent loss function selection system translates into significant industrial benefits. Improved imaging quality enables more precise control of technological processes, which directly affects the optimization of energy consumption. In addition, precise modeling reduces the risk of failures and production downtime, reducing operating costs. Automation of the model parameter selection process eliminates the need for manual intervention by specialists, simplifying the implementation of the technology in industrial environments.

The research results were illustrated in the form of comparative reconstructions obtained using different loss functions and recommendations of the classification system. Sample images can be found in the publication:

In summary, the presented research confirms that intelligent optimization of loss functions in neural models has a real impact on increasing the energy efficiency and safety of industrial processes. The developed classifier is a significant step towards automation and further optimization of reactor monitoring systems, opening up new possibilities for industry 4.0.

The full text of the publication is available in the journal Energies at:

https://doi.org/10.3390/en17030681