Modern Impedance Tomography for Industry: A Groundbreaking Solution by a Polish Research Team

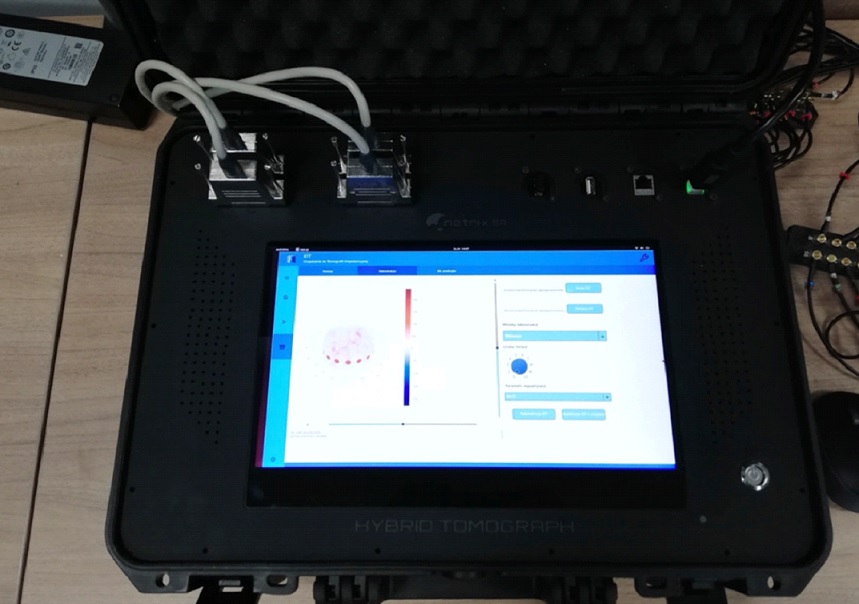

A team of scientists from the Research and Development Center of Netrix S.A. has developed a mobile impedance-capacitance tomography system that redefines the way technological processes are monitored and analyzed in industrial environments. This innovative solution enables non-invasive imaging of the interior of tanks, pipelines, and industrial equipment in real-time, providing critical information for quality control, production optimization, and failure prevention.

The developed system combines the capabilities of impedance tomography (EIT) and capacitance tomography (ECT), allowing for the visualization of impedance distribution and detection of process inhomogeneities. The use of modern image reconstruction algorithms, including Tikhonov regularization and Total Variation methods, ensures high-quality visualizations even in complex industrial conditions. The system is further enhanced by the ability to integrate data from environmental sensors, such as pH and temperature, which increases the diagnostic value of the analysis.

The technology is built on a modular hardware architecture – the use of measurement cards with flexible configuration allows the system to be tailored to various industrial applications. The device also supports 3D analysis and dynamic data presentation using visualization libraries such as Plotly and Video, enabling intuitive real-time monitoring of process changes.

Tests conducted on a tank with three controlled inclusions demonstrated high measurement repeatability, and Principal Component Analysis (PCA) confirmed a strong correlation between successive data series. This enables early detection of blockages, deposits, structural changes, or other anomalies that could lead to production losses or operational hazards.

The applications of the developed system are broad, covering industries such as food, pharmaceuticals, chemicals, petrochemicals, and mining. The ability to optimize mixing, monitor the technical condition of installations, and track the flow of raw materials makes this technology aligned with the principles of Industry 4.0, offering advanced support for decision-making and operational processes.

The full version of the publication is available at:

link to publication