Hybrid tomography system ETI, ETP and TU for industry

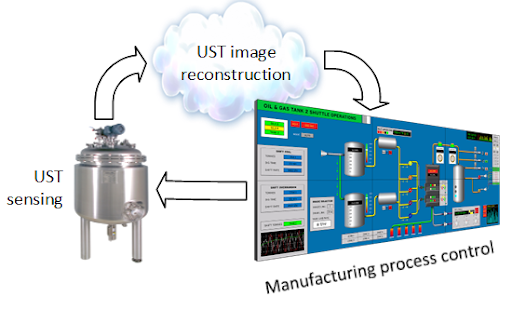

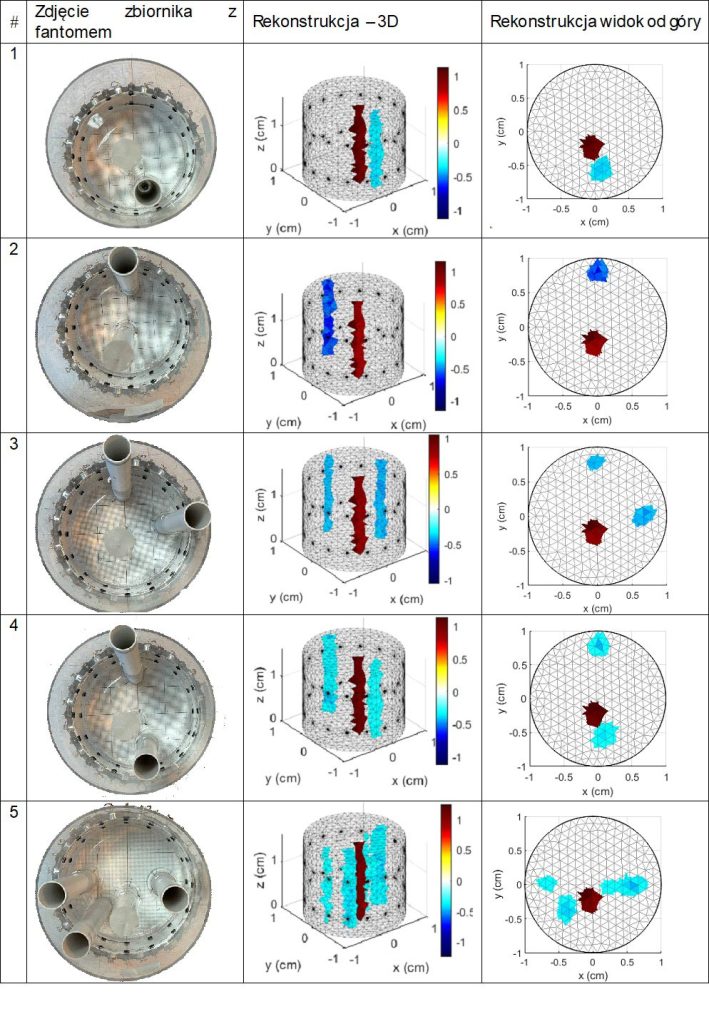

We present an advanced tomography system combining electrical impedance tomography (ETI), electrical capacitance tomography (ETP) and ultrasonic tomography (TU). Our solution is dedicated to monitoring and imaging phase states in tank reactors, providing precise data on industrial processes.

Why choose our system?

- Multidimensional process analysis

The combination of three tomography technologies enables accurate imaging of internal structures of reactors, such as liquid, gas and solid phase boundaries, as well as detection of gas bubbles and crystallization.

- Precision through machine learning

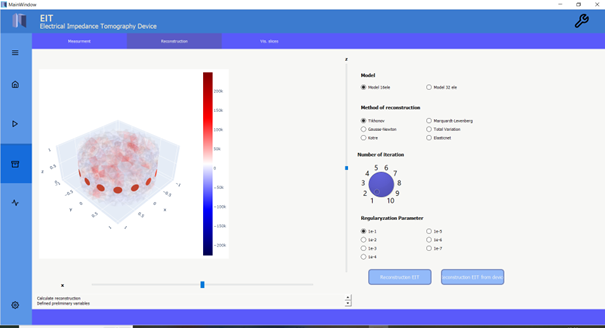

The system uses LSTM (Long Short-Term Memory) algorithms that precisely solve the inverse problem in tomography, transforming measurement data into three-dimensional spatial images.

- Non-invasive monitoring

Electrodes and sensors are installed on the external surfaces of the reactor, which eliminates process interference and allows for their ongoing control.

- Versatility of applications

The system is used in various industries, such as:

- Chemical and petrochemical industry – control of chemical reactions.

- Food industry – fermentation in the production of beer, yoghurts and other products.

- Energy and biogas plants – monitoring processes in biogas reactors.

- Pharmaceutical industry – control of crystallization processes and other key reactions.

- Paper industry – optimization of mixing and processing processes.

- Speed and accuracy

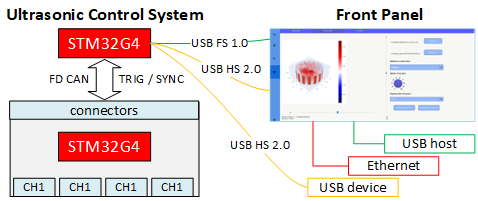

Thanks to the use of modern FPGA systems and an advanced data processing algorithm, the system provides real-time imaging, allowing for immediate reaction in the event of anomaly detection.

Technical specification

- Imaging methods – ETI, ETP, TU

- Spatial resolution – Highly accurate three-dimensional imag

- Processing time – Real-time image reconstruction

- Technologies used – Artificial intelligence, LSTM networks, optimization algorithms

Business benefits

- Reduction of operating costs thanks to precise diagnostics.

- Increased reliability of industrial processes.

- Infrastructure protection thanks to ongoing monitoring.

Please contact us to learn more and adapt the system to the individual needs of your company. Our hybrid tomograph is the future of industrial monitoring!

Mobile impedance-capacitance tomograph for flow analysis and optimization of technological processes.

The product is a response to the identified needs of target customers such as:

- Monitoring of technological processes

- Control and optimization of manufacturing processes

- Data processing and analysis

- Spatial analysis of technological processes

The target market for the designed solution is made up of industries such as food, chemical, pharmaceutical, petrochemical and mining.

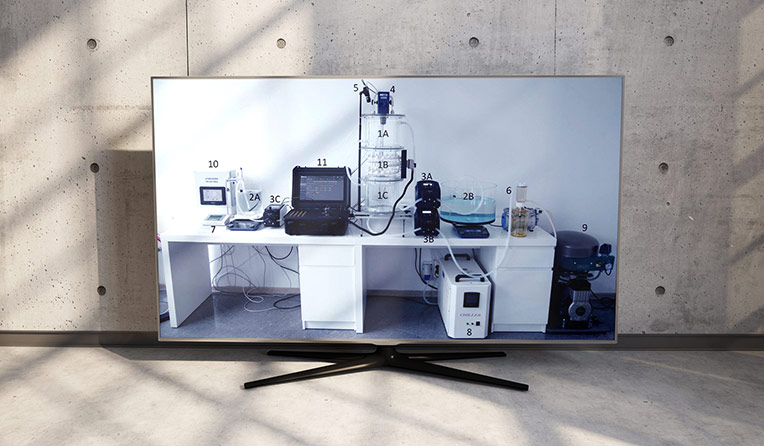

- Reaktor z dwoma płaszczami wodnymi do kontroli temperatury procesu oraz przetwornikami ultradźwiękowymi o częstotliwości środkowej 300kHz rozłożonymi w trzech pierścieniach w konfiguracji:

- Upper ring – 16 ultrasonic transducers 300 kHz

- Middle ring – 32 ultrasonic transducers 300 kHz,

- Lower ring – 16 ultrasonic transducers 300 kHz

- Dwa mieszadła magnetyczne z możliwością grzania i sterowania zdalnego wyposażone w:

- A 20 cm diameter acrylic glass tank filled with NaCo3 solution

- A 40 cm diameter acrylic glass tank filled with CaCl2 solution

- Trzy pompy perystaltyczne do:

- Dosing calcium chloride solution CaCl2

- Emptying the reactor after the crystallization process

- Dosing sodium carbonate solution Na2Co3

- Remotely controlled stirrer propellers for mixing the crystallizing solution

- Camera for inspecting the ongoing process

- Tank with a vacuum pump to separate the liquid part from the crystallized part

- Probe for measuring the temperature of the pH solution

- Chiller for controlling the temperature of the ongoing process inside the reactor

- Compressor for aerating the solution

- Demonstrator controller

Data analysis based on deterministic methods and machine learning.